Abstract - The design and installation of an impressed current cathodic protection CP deep anode ground bed system was carried out at Port Harcourt. Corrosion is usually defined as the deterioration of a metal or its properties caused by a reaction with its environment.

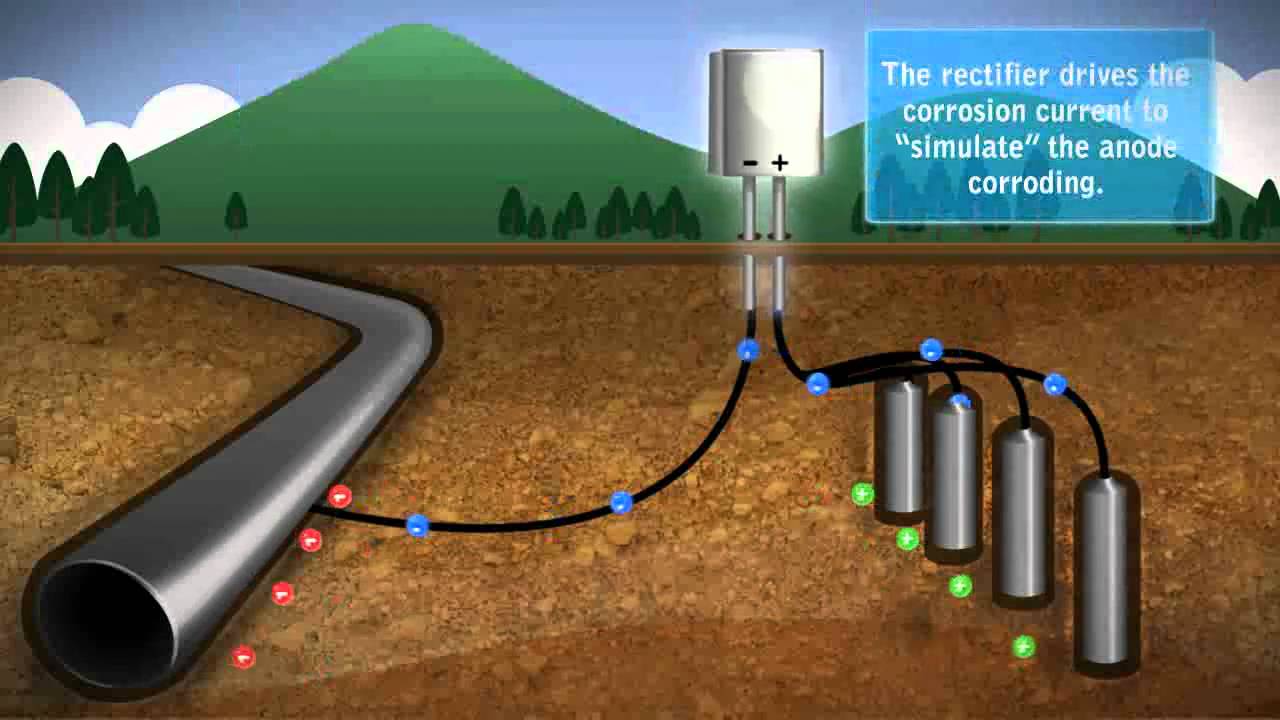

Cathodic protection system the design of anode ground bed plays very important role since the current distribution and pipe potential will be affected by anode position with respect to the structure position.

. The below factors are considered during the Design phase. Ground bed or groundbbed is a broad generic term to identify the location of one or more anodes installed in specific location in the ground. For extremely corrosive soil.

Locations for the groundbed and anode system. At Skydew Energy Services Ltd SES we believe you deserve excellent service and complete value such as is obtainable globally and we are ready to utilize all resources at our. The cathodic protection system has been designed to protect the underground pipe 11 Codes and Standards All the design and installation for cathodic protection system shall be in accordance with the.

In the case of iron the oxides will be in the form of ferrous or ferric oxide. Cathodic Protection Ground Beds. As compared with traditional grounding resistance evaluation.

For vertical anode installation holes shall be excavated in appropriate diameters and depth. A groundbed is an electrode array that is installed beneath the ground to give off a path with low resistance to ground. Cathodic Areas Anodic Area Pipe Wood Bed Block.

For example in a gas pipeline distribution system the. This week will discuss how cathodic protection works and how it can be applied in practice to protect metallic structuresFirstly well discuss some of the basic principles behind cathodic protection and we will see how some of the concepts you have learned in the other units are applied in a. CATHODIC PROTECTION SYSTEM DESIGN Presented By DENIS L ROSSI PE.

Anodic Ground Bed Installation. A low soil resistivity which would otherwise be classified as a highly corrosive soil is not the only factor which determines the location of the anode. 211 Physical dimensions of.

We design and install Deep Well groundbed and anode systems to distribute impressed electrical current for cathodic protection against corrosion on steel pipelines underground storage tanks and oil and gas well casings. All the design and installation for cathodic protection system shall be in accordance with the latest edition of NACE standards NACE RP 0169. MATCOR offers a wide range of ground bed anodes for cathodic.

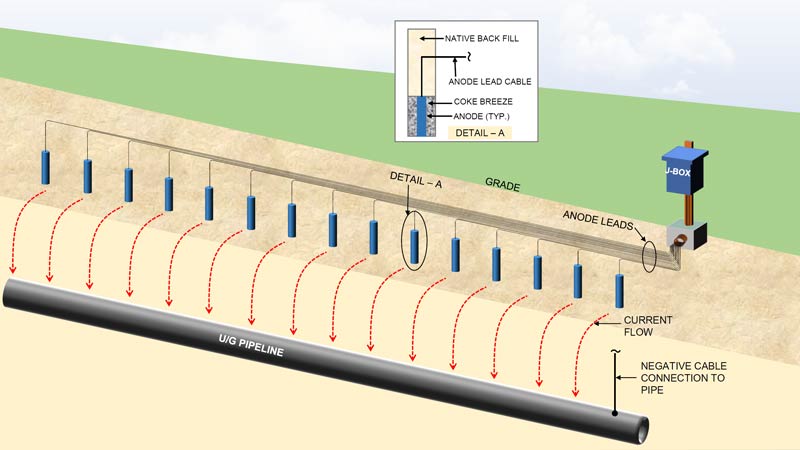

The installation checklist for surface groundbeds CATHDIC PROTECTION SYSTEM COMMISSIONING should be used. These are typically defined as an anode system consisting of a series of multiple individual anodes installed either vertically or horizontally at a depth of less than 15m 50ft and connected to a single power source. Galvanic anode CP systems provide cathodic current by galvanic corrosion or by sacrificing one.

When designing a deep well or horizontal bed cathodic protection system a primary objective is to ensure that the conductive backfill provides a low enough R-value ohms to enable the rectifier to achieve the desired. There are different types of ground beds and ground bed applications depending upon the asset to be protected easements and geographic restrictions that need to be factored into design. Physical dimensions of structure to be pro - tec ted.

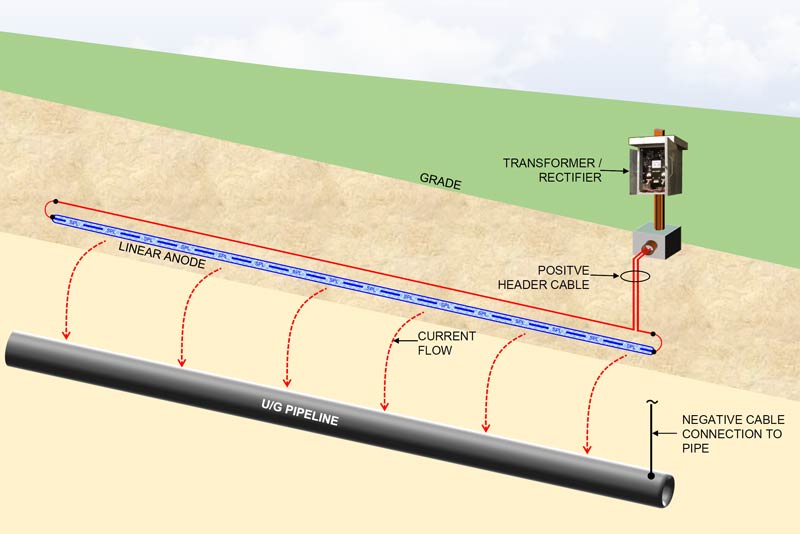

A common cathodic protection system approach is the use of a shallow horizontal anode bed. CORROSION ENGINEER New England C P Inc. Surface anode ground beds shall be constructed as directed by the design document.

Groundbed Design For underground structures requiring cathodic protection the location and nature of the site where the anode is placed needs careful consideration. Design Cathodic Protection Ground-Bed Arrangement with Finite Element Analysis Method. A deep anode system is an impressed current CP arrangement in which the anodes are.

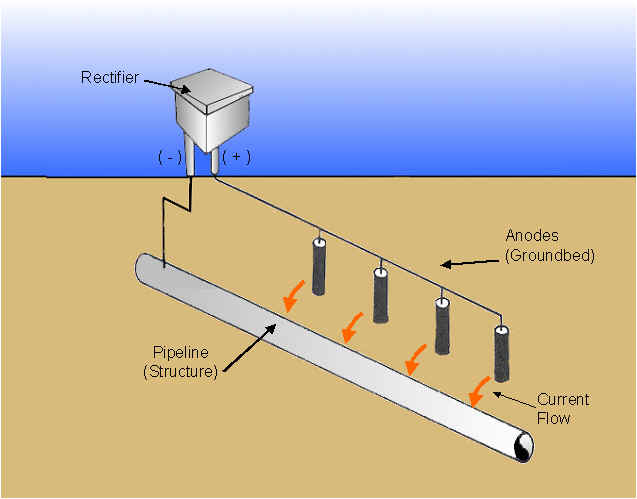

If a structure is to be protected by the cathodic system it must be electrically connected to the anode as Figure 1-1 shows. For materials and equipment IEC code -. Design Cathodic Protection Ground-Bed Arrangement with Finite Element Analysis Method.

This broad term could include further descriptive modifiers such as shallow deep anode vertical horizontal linear distributed or impressed current. At Point Integrity we have experience working with both galvanic and impressed current cathodic protection systems. Resistivity increases the corrosion rate decreases Before dec iding which type galvanic or impressed curre nt cathodic protection system will be used and before the system is designed certain prelimi-nary data must be gathered.

Design Cathodic Protection Ground-Bed Arrangement with Finite Element Analysis Method. We can provide unique and innovative design and installation techniques to aid in. From the lesson.

Most operators are faced with ground bed design issues due to environmental permitting and land acquisitionleasing difficulties. The two types of CP systems are galvanic anode and impressed current. Sometimes parts of a structure or system are electrically isolated from each other by insulators.

The below-mentioned steps are usually followed while designing a sacrificial anode cathodic protection system design. In terms of cathodic protection this groundbed refers to the anodes arrangement in water or ground which provides a way for protective currents out of anodes into an electrolyte. When exposed to oxygen and other oxidizing agents the refined metal will try to revert to its natural oxide state.

CATHODIC PROTECTION DESIGN 2-1. Cathodic protection is a means of reducing corrosion of a metal by artificially causing direct current to flow from external anodes through the electrolyte soil or water and onto the structure to be protected. As compared with traditional grounding resistance evaluation method which is only suitable for the case of each anode rod in a straight line the.

A more flexible grounding resistance calculation method based on finite element analysis FEA method is suggested which is especially suitable for optimization cathodic protection CP ground-bed arrangement. Monitoring and maintenance of Cathodic Protection Systems Installation and repair of Cathodic Rectifier and Transformers Ground bed design and installation. CATHODIC PROTECTION DESIGN 213 Electrical isolation.

4 rows For planning and design purposes it is often. GROUND BED GB DESIGN. Calculating the net driving potential for anodes.

Deep anode ground bed CP systems using photovoltaic PV modules have become an industry standard. We know you may have preferences eg manufacturer materials etc and we will work within your desired specifications and. Otherwise magnesium is used.

Resistivity increases the corrosion rate decreases Before dec iding which type galvanic or impressed curre nt cathodic protection system will be used and before the system is designed certain prelimi-nary data must be gathered. ScarredDamaged Surface Corrosion Threads scratches and dents are anodic to undisturbed surfaces along the pipe. A more flexible grounding resistance calculation method based on finite element analysis FEA method is suggested which is especially suitable for optimization cathodic protection CP ground-bed arrangement.

The engineering expertise in grounding has a direct relationship to the efficient design of a cathodic protection CP system. It is a vital component of the grounding system.

Shallow Horizontal Anode Bed Design With Linear Anodes Matcor Inc

Anodic Ground Bed Installation Alpha Pipeline Integrity Services Inc

Shallow Horizontal Anode Bed Design With Linear Anodes Matcor Inc

0 comments

Post a Comment