Giving us accurate noise calculations and optimal compact designs. Download our Vent Silencer Data Form.

Silencers P R Acoustical And Engineering Works P Ltd

You can fill it out and send it back to us for a quick quote.

. In standard gas or steam venting system the release of noise energy generally occurs at the point of open stack exit. This noise can be generated due to the high velocity flow through the valve and turbulence created around any obstacle in the line that suddenly arestricts or changes the direction of flow such. Hence the vent silencer should be installed either at the stack outlet or within the stack to intercept and dissipate this noise before it can escape into the environment.

They are equivalent silencer designs and are referred to as vent silencers when being used to vent at a constant flow rate for a period of time. To reduce work place noise levels to a desired occupational limit. If you need a tailored solution our steam vent silencers shop will engineer and manufacture industrial grade noise control waste recovery and emission control equipment with any combination of components.

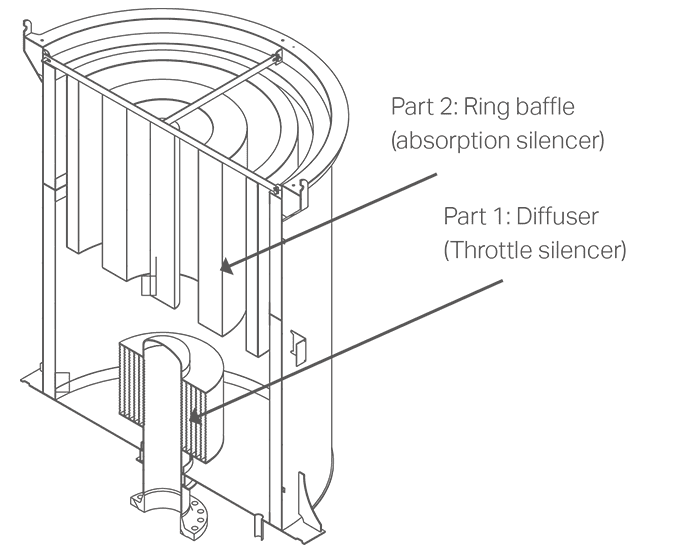

Then connect the discharge line low into the shed so that the flow has to be upward and over the partition wall and then back down towards some louvre vents the exit path is not direct. The pressure at the inlet diffuser Silencer performance of the IMS design of vent silencer is never more than 05 barg to ensure exemption from the requirements of the Pressure Equipment Directive. Vent silencer design The concentric annular ring design and the wrapped Acousti-Tube vent silencer design offer a choice of silencer profile and configuration to.

Sound is attenuated due to absorption conversion to heat Sound absorbing material eg duct liner Duct or pipe Types of Mufflers Design of Mufflers and Silencers. 1Type of gas 2Molecular weight or specific gravity 3Ratio of specific heats 4 Flow rate lbhr ACFM or SCFM 5Pressure and temperature upstream of valve and silencer 6Maximum allowable pressure drop PSI for valve and silencer. After a suitably sized device has been selected it is installed at the pipeline purge outlets where fluid expansion takes place.

When steam is relived Figure 1. Our state-of-the-art equipment enables us to manufacture and customize exhaust products to your exact specifications. To reduce the intrusion of industrial noise into residential.

Vent silencers serve a two fold purpose. Posted 16 February 2017 - 1128 AM. As the noise reduction specialist we are able to assess and meet your steam silencer needs.

The inlet of our silencers together with the noise generated by your valve is calculated using CONVAL-9. Engineering 2 University of Kentucky 1. The AFBR silencer can be mounted on any vent is easily installed and durable.

The steam into the surrounding air. They are referred to as blowdown silencers when they are blowing down a. Use the following design information from the valve data sheet for system analysis and silencer selection.

The vent silencer discussed here is those. STEAM SILENCER The steam silencer design is based on equations of an orifice plate that has several orifices or holes. The shed should be lined with fibreglass batts for absorption.

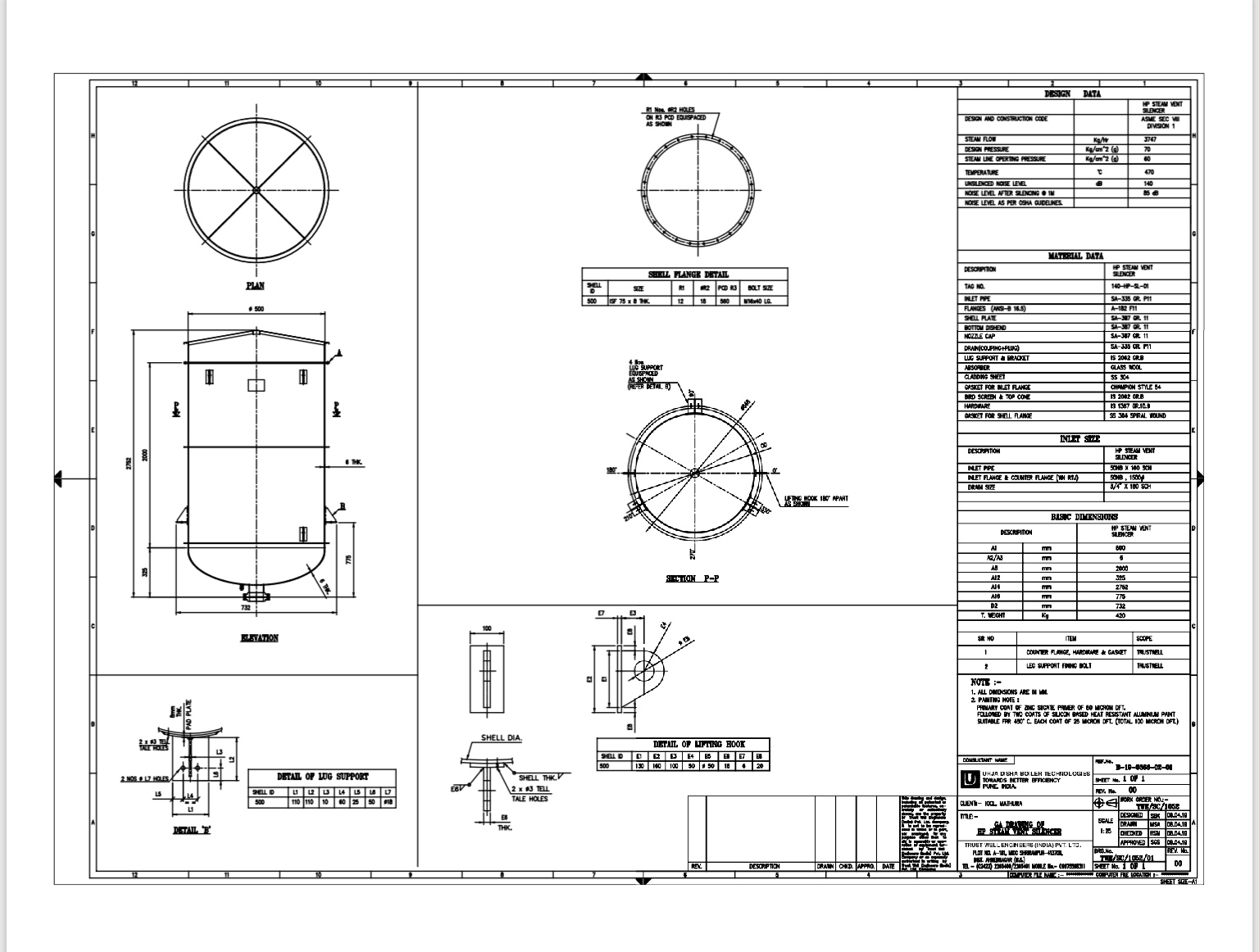

Efficient steam silencer design will reduce the noise level in industries that vent steam and other high-temperature fluids. The steam vent silencer model is generated using CATIA V5 R20 pre-processing is carried out using ANSYS WORKBENCH and CFX SOLVER is used for simulation. Vent Silencer Design At a given set of operating conditions each Vent Silencer is designed to attenuate the noise level to the required level criteria at a given distance from the silencer.

The plate is called a multi-orifice plate as seen in figure 1. They can be installed downstream any device acting as a link between a container of pressurized gaseous fluid and the atmosphere. Design of Mufflers and Silencers Noise and Vibration Short Course Dept.

Ventx is one of the best designers of industrial silencers in the UK. We can design products to suit various applications. VENT SILENCERS A vent silencer or a blow off silencer is a device used to reduce unwanted noise created by gas or steam flow in a pipeline discharging directly into the atmosphere.

Our Vent Silencers are designed to reduce the noise level of exhaust piping to the atmosphere for pressurized gaseous fluids such as air vapor natural gas nitrogen oxygen carbon dioxide etc. Note that the terms vent silencer and blowdown silencer refer to the application for which each is used. This sometimes necessitates an inlet diffuser diameter greater than the vent line.

Vent Silencer for discharging steam and gas - Koningsberger Str. Sizing Materials High Temperature Design. Ventx calculates the ejector noise and flow mixture.

In each case our goal is to reduce the noise to a less harmful level to protect people and the infrastructure. These orfice plates are the main characteristic of the system. General scheme of a multi-orifice silencer.

As customer requirements vary Ventx is always available to discuss any specific requirement. Depending on the flow velocity you may have to protect the fibreglass from erosion. Silencers that meet relevant noise standards.

Innovation never stops ASFC keeps on developing the silencers so you can enjoy the quietness. Please anyone having send stem silencer design calculation. The term vent silencer was derived simply for silencers used to attenuate noise produced by the expansion of Gas Steam or Air at elevated temperatures to atmospheric pressure.

Several factors are taken into. The two can be connected by a transition section. Ventx provides steam ejector silencers SES or gas ejector silencers GES which are specifically designed for use with steam or gas ejectors.

Our experts can also evaluate your entire operation and design a noise reduction system suited to meet all of your requirements.

Vent Silencer Vent Silencer Silencer Malaysia Selangor Kuala Lumpur Kl Shah Alam Supplier Supply Supplies Service Istiq Noise Control Sdn Bhd

Cross Section Of The Designed Double Muffler For Steam Vents Noise Download Scientific Diagram

Steam Silencers Trust Well Engineers India Pvt Ltd Leading Manufacturer Of Waste Heat Recovery Boilers Steam Coil Air Pre Heater Economizer Soot Blowers Steam Silencers Heat Pipe Recovery System In Pune

Vent Silencers Controlling Noise Creating Within A Pipeline From Gas Or Steamflow

Blow Off And Steam Vent Silencers

0 comments

Post a Comment